- Procurement

Resources

The Procurement Management Playbook

- 11 Best Procurement Software: Streamline Purchasing in 2024

- 13 Best Procurement Practices to Boost Sourcing in 2024

- 9 Essential Procurement Trends to Embrace in 2024

- 20+ Accounts Payable Automation Best Practices for 2024

- 10 Key Procurement Goals to Achieve in 2024

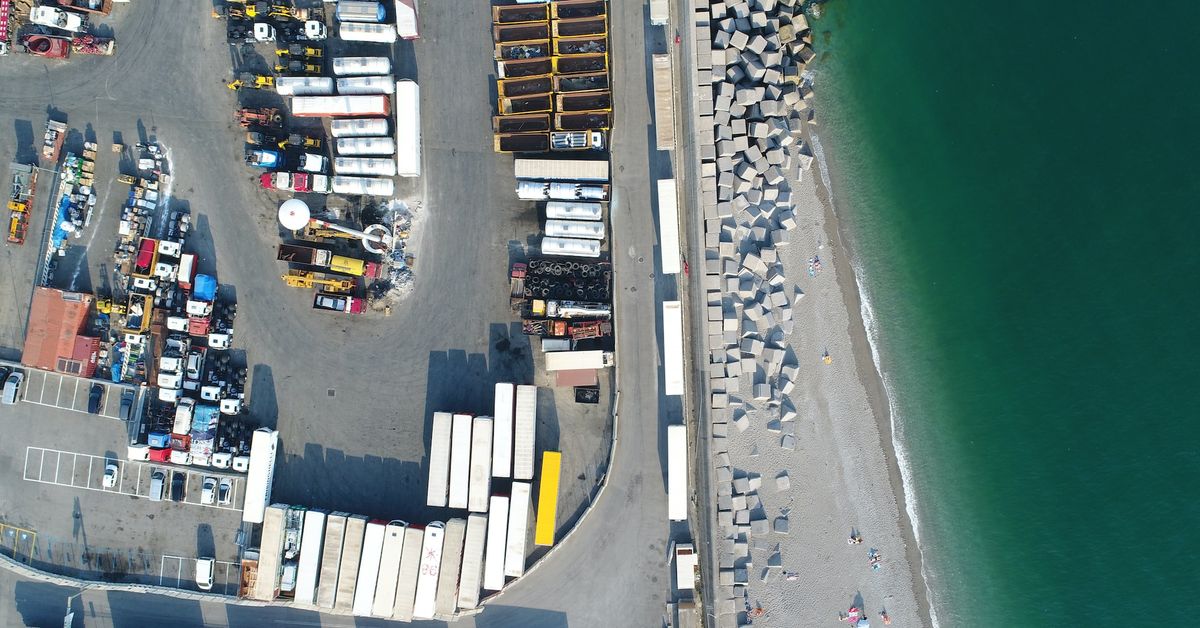

- Planning and Forecasting During Ocean Shipping Disruptions

- How and When to Use Tactical Sourcing to Grow Your Business

- Supply Chain Automation on a Budget (Improve Your ROI)

- What Is Invoice Data Capture (And How to Automate It?)

- Procurement Negotiation: How to Make It a Win-Win