Why?

Ineffective processes waste valuable resources.

Plus, they can damage customer relationships and workplace culture. The key to giving your business the best chance of success is process improvement.

But which processes should be improved? What’s the best way to go about optimizing workflows in a business? And finally, how can your organization avoid the pitfalls that cause process optimization to fail?

This guide to process improvement will walk you through everything you need to know about improving and automating your workflows.

From providing a deeper understanding of the various methodologies to the reasons why improvements fail to the best way to start improving your processes, you’ll learn what you need to know about process improvement in this post.

If you’re ready to figure out how to achieve successful process improvement in your organization, then read on.

What Is Process Improvement?

Process improvement is a way of analyzing business processes and looking for ways to streamline them. Businesses conduct process improvement with the goal of reducing waste, speeding up time to market, improving workplace culture, remaining compliant, and exceeding customer expectations.

Additionally, organizations that successfully implement process improvement typically see a return on their investment through optimizing workflows.

This can be through selling more products, providing better services, or getting more time to make strategic plays that provide an edge.

Process improvement follows one or multiple methodologies designed to evaluate existing processes and provide clear roadmaps for data-backed improvements.

The type of methodology/methodologies a business uses depends on the process they’re trying to improve, their objectives, their workplace culture, and the type of business they have.

The end result of process improvement is a more efficient way of conducting business. This could mean that redundant or wasteful processes are eliminated. It could mean that complex workflows are simplified and better matched to the exact needs of the business. And it could also mean that employees use new technology or automation to streamline processes.

When Is Process Improvement Finished?

For an organization to see the greatest results, process improvement needs to be continuous.

The way people conduct business is always changing. Customer expectations continue to grow and change as well. And new technologies are always being developed that impact the way businesses function.

As a result, business processes need to be continuously analyzed. Employees and executives need to keep an open mind, always looking for better ways to do business.

Organizations need to be aware of changes in the marketplace, new technologies, and growing customer expectations so that they can be ready to deploy new process improvements.

What’s the Difference Between BPI and BPM?

In short, there are many names for process improvement. And it’s not uncommon for them to be used interchangeably. These are several similar terms:

- BPM: Business Process Management

- BPI: Business Process Improvement

- BPO: Business Process Optimization

- BPR: Business Process Re-Engineering

- CPI: Continuous Process Improvement

While there are some slight differences in methodology or approach, the end result is typically the same: reduce inefficiency, risk, and waste in various processes.

Does Your Organization Need Process Improvement?

The short answer is yes. Every organization has processes that could be improved. With customer demands and the digital landscape changing all the time, the only way your business succeeds is to be forward-thinking.

That’s why it’s important to evaluate where improvements can be made.

Still, there are plenty of red flags you should be aware of if you’re wondering whether or not your business should push process improvement initiatives to the front of the line...

Warning signs that inefficient processes are slowing down your business:

- Continuous (avoidable) data entry errors

- Employees complaining about processes

- Poor workplace culture

- Increasing customer complaints

- Failing to meet deadlines

- Excessive unnecessary processes

- Growing approval bottlenecks

- Processes that don’t scale

- Decreasing bottom line despite increased revenue

The Power of Business Process Automation

Business process automation drives the efficiency of optimized processes further than you ever thought possible. While process improvement will save you a lot of time and resources, business process automation will give you a return not possible otherwise.

The key is knowing which processes to optimize and what platform you need to use. After all, with low code platforms, you can get enterprise-level automation without paying seven-figure price tags for custom coding.

Better yet, you can start off somewhere small and build from there. Start off by seeing why kind of returns optimizing workflows with low code can get you. Then scale your business transformation from there.

Don’t worry.

With the right approach, you’ll soon watch your competitors drift past your side mirrors.

Effects of Inefficient Processes

Inefficient processes can have a major, negative impact on your business. Here are just a few issues that unoptimized workflows can cause in your organization:

- Increased Costs: Inefficient processes were time and money through unnecessary redundancies, missed opportunities, and excessive waste.

- Poor Communication: Start and stop processes with too many extraneous steps open the door for miscommunication, resulting in more errors or downtime.

- Weaker Customer Relationships: Inefficient processes use vital time and resources needed to improve the customer experience.

- Unnecessary Tasks: Without evaluating workflows, there may be several unnecessary, meaningless tasks that could easily be removed.

- Increased Risk: Every human touchpoint in a workflow opens the door for potential risk.

- Constant Delays: Unoptimized processes can have several bottlenecks that reduce response time or time to market, putting the whole business at a disadvantage

Process Improvement Methodologies

There are several different approaches a business can take to optimize its workflows. For the most part, organizations use a blend of Lean and Six Sigma and/or Kaizen to address inefficiencies in the workplace.

But they’re not the only methods out there.

These are the main process improvement frameworks that businesses use to optimize workflows:

Kaizen Method

Kaizen is Japanese for “better change”. In short, it’s a mindset for everyone in an organization (from entry-level employees and support staff to the CEO) to look for ways the business can be improved.

The goal is to optimize workflows, improving the quality and efficiency of the business while reducing costs or waste (known as “Muda”).

Everyone is encouraged to think outside the box and find different ways to improve processes. Process improvement is continuous and everyone shares their insights on a regular basis, looking for ways to improve workflows.

Under the Kaizen Method, employees use data and experience to guide process optimization. Everyone is on board because they understand the overall organizational benefits of cost reduction.

Kaizen Uses Two Models To Improve Results:

- 5S Model: The five steps are Sort, Straighten, Shine, Standardize, and Sustain. The goal of the 5S model is to help team members focus their efforts. Process improvement involves going through each step to maximize waste reduction.

- Plan, Do, Check, and Act (PDSA): Organizations need to find problems (Plan), build solutions (Do), Evaluate results (Study), and deploy permanent solutions if they’re successful at improving workflows (Act).

Six Sigma

The main goal of Six Sigma is to reduce defects in production. The target goal originally was to aim for 3.4 product defects per 3 million opportunities. In short, the goal is as close to perfection as you can get.

Team members that manage process improvement using Six Sigma are typically given blackbelt names, “White, Yellow, Green, Black, Master Black Belt, and Champion.” (There were problems with this approach.)

The Six Sigma process improvement model relies heavily on data and statistics to suggest workflow improvements (though common sense and reasoning counts, too).

It uses one of two frameworks for process optimization: DMAIC and DMADV.

DMAIC vs. DMADV

- Define the problem or opportunity: Create a list of definitive goals with your team that the project hopes to achieve. This will keep you focused and make tracking the progress and success of your process improvements easier.

- Measure the existing process. Create a list of agreed-on CTQ (critical-to-success) factors. These factors should be easily measurable goals.

- Analyze the available information on current performance. Look at how and why the current state is different from the desired state. Try and find the gaps and their root cause. You're trying to understand the inefficiency in its entirety here.

- Improve/Design the solution. Assess the possible ways to overcome the defined gap. A cost-benefit analysis should help find the options that work best. Next, the team should run an experiment or a pilot project to test the approach. Measuring the CTQs of the pilot is uber-important. This will help verify the success of your process improvements.

- Control/Verify. Make sure your new processes cascade throughout the relevant parts of the organization. You'll need a lot of communication to assure your staff embracing the process improvement. And if you're developing a new product or workflow, this stage serves as a point to verify with the client that the outcome meets their needs.

It’s important to note that much of Six Sigma has gone out of style over the years. While it had its heyday in the late nineties, most process improvement specialists found better solutions.

Specifically, they sought to combine the benefits of lean process improvement with business process automation. Simply put, technology and the right framework provide a much better chance for optimizations to succeed over awkward methodologies (like belt colors for trainers.)

Lean Process Improvement

Lean process improvement focuses on waste elimination. Speed to market, better workplace culture, and better customer relationships are all side-effects of waste reduction resulting from lean process improvement.

Lean improvement focuses on reducing:

- Product Defects

- Excessive Production

- Inventory (Either from Over- or Underproduction)

- Transportation/Motion

- Waiting Periods

The 5 Whys

Lean primary focuses on getting to the bottom of the issue. That requires positively identifying problems and what might be causing those issues. This method involves getting a team together and asking why there is an issue.

The team follows up by asking “Why?” again (several times) in an attempt to discover more problems and what might be causing them.

Total Quality Management (TQM):

Total Quality Management (TQM) also uses data, strategy, and communication to drive process improvement by focusing on customer satisfaction.

The success of process improvement efforts (from employee training to the software an organization onboards) is evaluated by its direct impact on the customer.

The better the customer relationship after implementing an improvement, the more successful the optimization was. Here is how to define TQM:

- Customer Satisfaction: The customer determines the level of quality needed.

- Strategic Management: The organization sets out a clear path for optimizing workflows designed to support customer needs and improve engagement.

- Clear Communication: Communication is vital to successfully deploy, analyze, and improve workflows.

- Data-Based Decisions: Employees collect data on customer experiences and processes to lead process improvements.

- Organizational Involvement: Everyone in the organization focuses on improvements and process optimization as part of their role.

- Integrated Systems: All business systems are connected. All employees must understand organizational goals and work to build systems that support those goals.

- Continuous Process Improvement: Everyone in the organization regularly evaluates systems, looking for potential problems and improvements.

Theory of Constraints

Every project has at least one constraint. By focusing on a single process with the goal of identifying constraints, team members can quickly identify key elements that may be causing waste.

Once those areas are identified, the next step is to find ways to reduce those constraints with efficient processes.

The theory of constraints uses a focusing process to find roadblocks that slow down a process. This five-step process creates a roadmap designed to help optimize the process.

- Identify the constraints: Analyze the workflow and identify the issue.

- Exploit the constraints: Improve processes and systems with the right tools and procedures.

- Subordinate everything else to the above decision: Improve processes and systems with the right tools and procedures.

- Remove/Reduce the constraint: Look for other ways to improve the workflow if the problem still remains.

- Repeat: Continue to optimize the process while looking for other areas in your business to improve.

General Process Improvement Tools

Effective process improvement relies on established frameworks and strategies to guide an organization’s efforts. These are 5 essential tools you should use to support your goals.

- Cause and Effect Analysis: Also known as a fishbone diagram, involves looking backward and forward to identify problems in your organization and how you can develop solutions to them. You can use the diagram to find roadblocks and problems that prevent your organization from achieving its goals.

- Root Cause Analysis (RCA): The process of finding out the real cause of workflow inefficiencies rather than focus on issues that might simply be symptoms of the main problem.

- Kanban Board: Project management tool designed to help users visualize processes. It uses cards and columns to map out workflows against desired outcomes for your team to see.

- Process Mapping: A visualization tool for workflows that shows the detailed steps of each process. It allows team members to quickly identify slowdowns, redundancies, and waste in any business process.

- Current Reality Tree: A visualization tool that helps identify the problems in an organization that weaken processes and outcomes. At the top of the tree is the undesirable effect (UDE), then you have the intermediate effects. Finally, you have the root causes. It helps paint a realistic picture of the organization.

- Gantt Chart: A visualization tool that uses bars to track progress on projects. Tasks are listed on a vertical axis while time is listed on the horizontal axis. The bars used to track tasks reflect the time needed to complete the task. This allows people to quickly see how the steps of a process break down into parts and how long each part lasts.

- Process Modeling: This goes into more detail than process mapping, providing insights into the workflow and how it impacts the entire business. The end result is focused on an analysis of the process and how it can be improved.

- SIPOC Analysis: Diagram tool that outlines all the necessary steps to improve a project before the process improvement starts. In short, it helps define a clear scope and list of materials needed to improve any workflow. This can happen during the “measure” stage of DMAIC or any other process improvement framework.

- Swimlane Diagrams: Focus on the major players in a process (who does what), adding an extra dimension to flowcharts. These diagrams also show communication, handoffs, and other interdepartmental interactions important to a particular workflow.

- Time Audits: This approach requires timing processes to get an accurate understanding of how much time is required to complete certain processes. As a result, accurately measure the results of process improvements.

- Value Stream Mapping (VSM): Flowchart that helps further document the steps in a process. VSM can help identify wasted time and resources during a process. It helps organizations stay lean by evaluating the value of each process component.

- Work in Process Limits (WIP): This approach requires team members to set up time limitations for themselves on tasks, driving them to work more efficiently. As a result, team members avoid the temptation to switch tasks when they reach bottlenecks.

As a general rule, each business adapts these process improvement frameworks to their specific needs.

In the end, businesses can rely on one model more than others, or hybrids of multiple models, depending on their needs. And they can use various process improvement tools as well.

With the right experience and training, you can use these tools and mindsets to quickly find the problems in your workflows and come up with solutions to test.

There’s also a range of process improvement software tools out there your organization can use. But we will cover those later on.

For now, we’re going to focus on the steps you need to follow to start improving the workflows in your business.

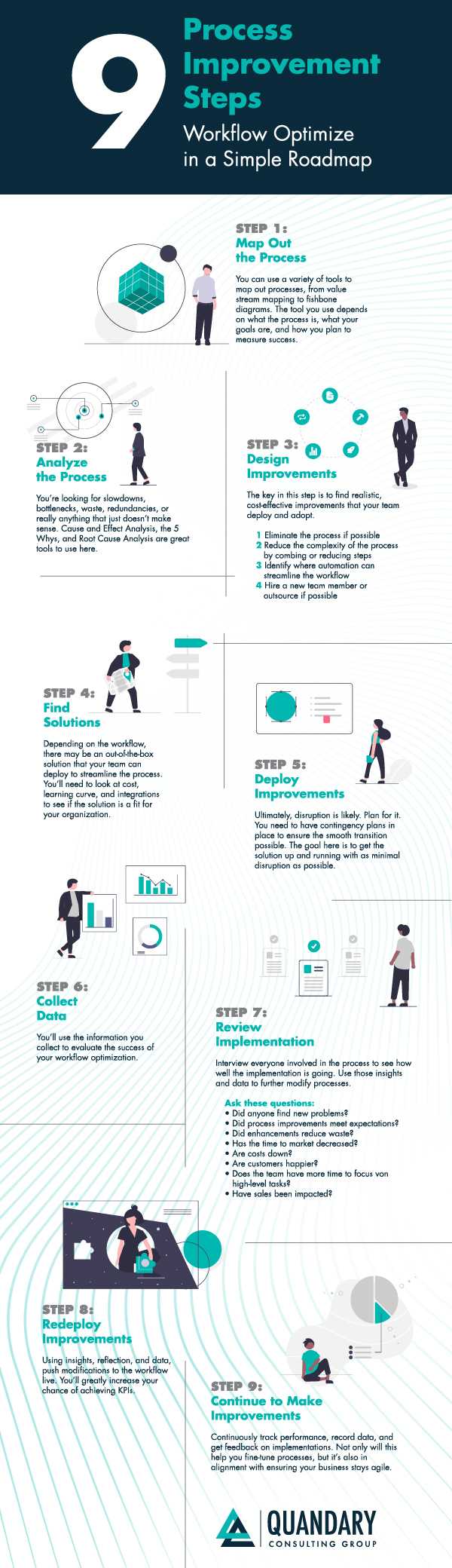

9 Process Improvement Steps [Easy to Follow Framework]

Effective process improvement involves following a set of frameworks designed to avoid the common pitfalls of process optimization. If you want to get the most out of your improvements, you need to follow these steps.

Otherwise, you may end up wasting more time and money while failing to make the critical changes your organization needs.

If your organization is just starting out with process improvements, it’s best to pick a small process and go from there. As your team becomes more familiar with the steps and sees success, you can tackle larger processes.

Step 1: Map Out the Process

Process mapping should be your first step. You can use a variety of tools to map out processes, from value stream mapping to fishbone diagrams. The tool you use depends on what the process is, what your goals are, and how you plan to measure success.

Your main focus should be to try and fully map out each and every step in the process.

That means you should consult employees who are directly involved with the process you’re looking to improve. This will ensure you don’t miss anything.

Step 2: Analyze the Process

With the process fully mapped, the next step is to analyze the workflow. You’re looking for slowdowns, bottlenecks, waste, redundancies, or really anything that just doesn’t make sense.

Cause and Effect Analysis, the 5 Whys, and Root Cause Analysis are great tools to use here. These frameworks will help you better understand the rationale behind the process and where the breakdowns are. As a result, you’ll be in a better position to design solutions.

You also want to collect a baseline for data here. Before you deploy any improvements, you need to know whether or not your efforts made a real, measurable difference.

Collect data for a predetermined period of time and use that as a baseline to compare your efforts after you launch your process improvements.

Step 3: Design Improvements

Once you’ve mapped out your process, consulted with your team, and figured out the source of your workflow inefficiencies, you need to design solutions.

Solutions can be as simple as removing steps to the process or they may involve more complex measures like deploying automation or building custom applications to better support the workflow.

The key in this step is to find realistic, cost-effective improvements that your team can not only deploy but will adopt moving forward. After all, failing to adopt solutions is one of the main reasons process improvements fail.

Adoption is such a vital part of process improvement that you should work with employees directly involved in the workflow to come up with solutions. Their expertise is too valuable to ignore. Plus, it helps ensure that you’ll see the highest possible ROI.

After you draft up potential solutions, you’ll want to run them through certain process improvement frameworks like Impact Analysis, Risk Analysis, Failure Mode and Effects Analysis, and Customer Journey Mapping.

Using these frameworks will help understand the impact the new process may have on your business, any potential risks, and what could happen if parts of the process break down.

Finally, with Customer Journey Mapping, you can see things from your customers’ point of view, ensuring that they remain the central focus for your business improvements.

When it comes to creating solutions, try to keep it as simple as possible unless complexity cannot be avoided. You should try to:

- Eliminate the process if possible

- Reduce the complexity of the process by combing or reducing steps

- Identify where automation can streamline the workflow

- Hire a new team member or outsource if possible

Step 4: Find Solutions

When you cannot simply reduce, combine, or eliminate steps in any given process, you need to look for solutions. Typically, these will be third-party solutions and will come in the form of either outsourcing or software.

Depending on the workflow, there may be an out-of-the-box solution that your team can deploy to streamline the process. You’ll need to look at cost, learning curve, and integrations to see if the solution is a fit for your organization.

Alternatively, you can also outsource tasks to vendors who specialize in complex workflows that might be too complex or cost-intensive to handle in-house. Or, you may need to onboard a new team member to handle the role.

Either way, you need to map out the right solutions for your organization that fit your budget, workplace culture, and your business.

Step 5: Deploy Improvements

This is perhaps the most challenging part of process improvement. Deploying improvements is not as simple as flipping on a switch. Sometimes, you need to transition from one software platform to another. This can cause delays or downtime.

If you’re outsourcing, there most likely will be a learning curve for your vendor. And if you need to hire a new team member, you need to be ready for the time it will take to onboard them for the new role.

Ultimately, disruption is likely. Plan for it. You need to have contingency plans in place to ensure the smooth transition possible.

The goal here is to get the solution up and running with as minimal disruption as possible.

Step 6: Collect Data

The key to knowing whether or not a process works is data. Now is the time to collect data and compare it to the data you collected at the start of your optimizations. You’ll use the information you collect to evaluate the success of your workflow optimization.

Step 7: Review Implementation

From the moment your new workflow goes live, you’ll want to monitor it. There are several questions you can ask to evaluate the impact of your process improvement:

- Did anyone find new problems?

- Did process improvements meet expectations?

- Did enhancements reduce waste?

- Has the time to market decreased?

- Are costs down?

- Are customers happier?

- Does the team have more time to focus on high-level tasks?

- Have sales been impacted?

You’ll want to interview everyone involved in the process to see how well the implementation is going. And you’ll want to use those insights along with the data collected to further modify processes.

Step 8: Redeploy Improvements

With the right insights and reflection, you’re ready to redeploy implementations. You’ll have an updated workflow based on real insights. As a result, it’ll have a much better chance of achieving KPIs.

Step 9: Continue to Make Improvements

Process improvement isn’t a one-and-done process. You need to continuously track performance, record data, and get feedback on implementations. Not only will this help you fine-tune processes, but it’s also in alignment with ensuring your business stays agile.

After all, businesses are always changing and growing. The best businesses, the ones that stay competitive (and last) are the ones that are reflective. Your organization should always be looking for better ways to function and meet customer expectations.

Otherwise, you’ll lose your competitive edge. And that’s the value of continuous process improvement.

There Are No “Sacred Cows”

When it comes to improving processes, everything is up for discussion. It’s important that you analyze any and all variables at each process. There is always a better way to do something.

Many of the legacy processes may no longer work as well as they once did. Failing to question whether or not there are better ways or tools to carry out these tasks can put you at a major disadvantage.

When it comes to process improvement, remember that there are no sacred cows. Analyze everything. Don’t hold back. Be prepared to break down legacy systems and rebuild workflows.

What Is Continuous Process Improvement

Continuous process improvement is the act of regularly evaluating how a business functions, looking for opportunities to reduce waste while improving customer satisfaction and workplace culture.

In short, it’s process improvement on an ongoing basis. And it requires organizational-wide buy-in. Additionally, continuous improvement isn’t isolated to inefficient processes. Instead, it’s a way of constantly looking for ways to improve any and all processes within an organization.

While the methodologies discussed previously have elements of continuous process improvement in them, they’re not synonymous with a continuous process improvement approach.

Continuous improvement strives to add value to the business on a continuous basis. There is no destination with continuous improvement. Instead, it’s a cyclical approach. Your team will regularly evaluate, plan, deploy, and evaluate improvements in your organization.

What Is Process Standardization (Why Is It Important)?

Every process in an organization should have guidelines everyone should follow to carry out each task. These guidelines should be designed to reduce waste while ensuring the end customer gets the highest possible quality service or product.

Process standardization establishes these rules by setting specific guidelines in place for employees to follow. By having these guidelines in place, you ensure that any process improvements you implement are in alignment with the business goals and standards.

The end result of process standardization is increased clarity, productivity, and morale (after all, with clearly stated procedures in place, your staff won’t stress trying to figure out what needs to be done.) Additionally, you’ll ensure that each process aims to improve customer satisfaction.

Processes Optimization vs Process Improvement

Process optimization attempts to maximize the efficiencies of process improvement. Think of it as squeezing out “more juice” from already streamlined processes.

Process optimization follows the same path of process improvement. You look for problematic processes, analyze their performance, design and deploy optimizations. After you track performance and fine-tune your optimization to get the most out of a specific workflow.

Where process improvement aims to streamline a process, process optimization is all about maximizing a workflow’s potential. If process improvement gets you to 90%, optimization is about getting your organization that extra 10%.

3 Real-World Process Improvement Examples

While it’s easy to talk about process improvement, in theory, bringing solutions to life can be a very complex process. Still, process improvement is very achievable and the results are very tangible for any organization.

Here are 3 real-world examples where effective process improvement led to real results.

Custom Application Reduces Labor at Over 9000 Locations

Invoicing Portal Saves $6,000 Monthly

Streamlined Employee Review Process

A nationwide company with 9,200 free-standing stories (including pharmacies, clients, and other services) manually managed service requests at each location.

After analyzing the processes in place, we built a custom application designed to help them automate these tasks.

Using the platform, store managers can enter the information they need for a maintenance request. From there, the platform tracks the request and alerts the required parties.

The platform reduces labor costs by a minimum of one hour per location.

A large Facilities Maintenance and Construction Company was tracking 5,000 vendors and processing invoices manually. Missed payments and late fees happened regularly.

Additionally, there was no single system to provide transparency. Invoices were lost. Data entry errors happened. And costs drastically increased.

We built a custom invoicing system in low code for the company. This provided clear visibility into their vendor management. Additionally, it allowed their team to effortlessly track invoices and data in one accessible system.

The end result was a cost reduction of $6,000 per month, easily providing a clear ROI.

A nationwide organization was struggling to effectively track and manage employee performance reviews. They needed a way to conduct 30 days, 90 days, and annual reviews.

Without a system in place, review dates were missed and data went unlogged or missing.

After working with the organization to discover the root cause of their inefficient process, we built a custom review platform that automated the employee review process.

The system sends out reminders for evaluations, summarizes assessments, and stores results. Now the platform tracks over 480 employees and their performance without issue.

You can find more real-world examples of process improvement here.

What Are the Best Process Improvement Software?

There are a lot of process improvement tools on the market to help you streamline workflows and automate your business. Whether you’re a startup, a growing company, or an enterprise organization, you have your options.

However, it’s important to note that the focus should always be on improving the workflow, not deploying the latest technology.

Instead, it’s best to think of automation as a way to exponentially increase the efficiency of established processes already in alignment with your business and customer goals.

If you’re in the market for software that will help streamline your processes, then you should take a look at the leaders in process improvement software. These platforms will help improve your processes.

Monday.com

This project management tool helps businesses create custom applications and manage their team to improve processes. It uses a simple interface that helps team members organize tasks and track projects. Additionally, users can collaborate and get clear data insights. Plus, the platform supports integrations to help automate workflows.

Pipefy

Pipefy is a no-code platform designed to help businesses streamline their workflows with a simple visual interface. Users can build end-to-end process automations, eliminating the need for people to spend time on repetitive tasks. Teams also get the security and transparency they need with a platform that keeps communication and process tracking in one convenient place.

Process Street

Process Street is a cloud-based business process management solution that helps businesses automate workflows. Users can get support with customer onboarding, HR support, Help desk support, and more. Plus, the platform offers a range of features such as project management, permission controls, and web forms. And with Zapier, it can connect to 100s of applications.

Tallyfy

Tallyfy provides a simple way to automate processes in your organization. The platform lets you document, track, and deploy process improvements. It also has a dashboard for clear, real-time reporting. And it integrates into a variety of existing, third-party programs. Best of all, Tallyfy streamlines the decisions and approval workflow, helping to reduce major process bottlenecks.

Integrify

Integrify is a low code platform that helps organizations automate menial tasks with automation and integration. Users can streamline process improvements and track performance using real-time dashboards. The platform focuses on HR, Finance, Technology, Sales, and Operations workflows. And it can function as a cloud-based, on-premise, or hybrid application.

Automation’s Role in Process Improvement

Business process automation is critical to getting the most out of your process optimization. However, even if you don’t deploy software solutions and simply focus on simplifying your processes, you’re better off.

After all, you’ll walk away with well-documented processes that reduce waste. Still, automation is required to take your process improvement to the next level.

Business Process Automation

Human beings suck at manual tasks. We get distracted because we get bored, and make mistakes. Plus, we’re very, very slow at data entry and merging disparate data streams.

The end result is a messy process that leaves people exhausted, hating their jobs, and stressed that they’ll make catastrophic mistakes.

Automation avoids that mess by removing the human component and letting the machines do what they do best. While standard measures of process improvement can ensure your processes are necessary and optimized, automation is the only way to drastically reduce waste.

With the right software solutions and integration, your organization can accelerate processes beyond the capabilities of what the best employees could ever hope to achieve.

Ultimately, you’ll drastically reduce labor costs. Plus, because many automated solutions are secure and accurate, you’ll drastically reduce risk to your organization.

Robotic Process Automation (RPA)

Robotic Process Automation further streamlines automation using bots that mimic human actions. Programmers can set up bots with a range of triggers that automatically deploy when an action occurs.

In short, it can completely remove the need for a human element in many complex processes. This gives your team more time to focus on delivering white-glove customer service and developing more strategic processes.

Whether you want to automate email, transfer data between systems, manage entire supply chains, streamline employee onboarding (or most HR processes), RPA can push process automation to the next level.

Why Business Process Improvement Fails

The outlook for process improvement doesn’t look good for most businesses. According to research by McKinsey, 70% of process transformations fail.

Sadly, most of these failures could have been avoided had organizations taken the right steps to improve their processes. Instead, most companies fail because they fall into these traps.

-

Focusing on The Wrong Issue

If an organization fails to identify the real cause of the slowdown, it may end up focusing on streamlining side-effects of the underlying condition. As a result, their success is minimal.

Worse still, if a business focuses too heavily on the framework, it may get sidetracked with terminologies and methodologies that don’t get it further toward its goals

Instead, businesses need to go deeper and identify the real cause of inefficiencies. By addressing the root cause of the problem, you’ll reduce waste and get better outcomes.

-

Not Working With Team Members

Data should drive your process improvement, but it isn’t the only source of information you should consult. Failing to consult relevant team members regarding process improvements could result in wasting a lot of time and money on a solution that simply doesn’t work.

Working with the department whose process you’re trying to optimize is critical to ensure new solutions are onboarded. Plus, their unique insights help reduce the likelihood that you’ll overlook anything major.

-

Lack of Support

For process improvement to succeed, you need top-down support in your organization. A negative view of improvement reduces buy-in and reduces the chance that any changes will be long-lasting.

Work with your leadership to cultivate a culture of change in your organization.

Everyone on your team should understand the overall goals of improvement and the impact it will have on their role in the company. They should also be encouraged to find other areas to improve and support existing optimizations.

Poor Communication

Clear, open communication is key for any successful process improvement. Changing how business functions can cause a lot of disruption. Even if the old way of doing things is expensive and time-consuming, if people don’t know what to expect, they’ll cling to old, inefficient ways.

Keep everyone in your organization informed about your process improvements. They should be aware of any potential disruptions and have clear insights into what the overall goals for each process improvement are. With everyone focused on the same goals, you’ll avoid failure.

Ineffective Technology

Selecting the wrong process improvement software can be an expensive mistake. If you go with an out-of-the-box solution, you may end up paying for features you don’t need. Worse, you would miss out on key features that you do need.

Either way, you’re stuck trying to force your business into a model made by your tools.

Choosing the right technology to help improve your process is vital. Whether or not you leverage custom solutions or an off-the-shelf solution depends on your budget, goals, and workplace culture.

Don’t assume that a successful solution will be successful for your business. You’ll need to do your research to ensure you invest in the best platform.

Team Up with Process Improvement Consultants!

There are a lot of important variables to consider when conducting process improvement on your business. Business process automation combined with the right strategy for your business will go a long way to improving your processes.

However, there are a lot of great tools and methodologies out there. Which one works for your business depends on your goals, workplace culture, and customer needs. And if you want the best chance at successfully streaming your processes, then you need more.

The key is to leverage experience.

Experience will put your business in the position to successfully transform how it functions, giving you the resources you need to scale. And the best way to gain access to that experience is by working with trained process consultants.

At Quandary Consulting Group, our process consultants can help you improve your workflows and systems by building custom applications and integrating your disparate systems.

Always within budget. Always delivered on time.

Leveraging the power of rapid application development, low code platforms, and our extensive expertise, we help free businesses from clunky processes and manual systems.

All you need to do is share your objectives with us.

After we know your goals, we design, build, and deploy the custom scalable solutions you need to streamline your growing business.

And with a 100% adoption rate, our results speak for themselves.

Learn more about how we can help you integrate your workflows and steal back time from your business by exploring our services today.